Gas gensets

Gas gensets: smart energy solutions

We supply all the energy and the resources you need for your project, by guaranteeing the constant quality of our products, systems and services, for both simple (gas gensets) and complex (cogeneration power plants) installations.

From the simple supply of gas gensets, to the complete installation of a gas-fired backup power plant or a cogeneration power plant, our engineers can propose solutions that meet all the needs of your project:

- Consulting: an assessment of your current and future energy needs, a financial analysis based on the energy balance and the design of the installation, the environmental specifications, etc.

- Production start-up: completion of the administrative formalities and the formalities for the connection to the gas grid, installation and start-up on time and in accordance with the environmental procedures, command of the operation of the electric and thermal equipment, training, etc.

- Maintenance: contractual support, continuous service, on-call interventions, contractual guarantees, etc.

Our technicians and project engineers have all the means required to install your gas gensets and to guarantee their long-term profitability and safety.

Eneria designs and builds turnkey power plants. We have broad based experience in both project management and the specific technologies, from backup electricity systems, to the combined production of heat and electricity (cogeneration) and the production of electricity from biogas. Finally, we can propose funding solutions for all your projects.

We offer a complete range of gas or biogas gensets, from 400 to 4,500 kWe, that can provide the best solution to your needs for heat, cold or electricity, and optimal profitability.

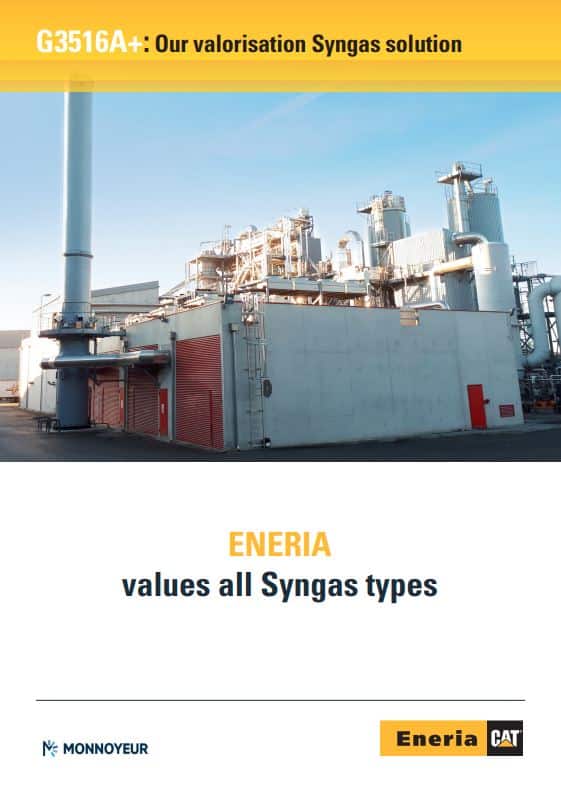

Find out more about Eneria’s expertise in synthesis gas

On the strength of its experience in the recovery of synthesis gas since 2006, Eneria now proposes the Caterpillar G3516A+ genset, which has already demonstrated its performance with syngas from gasification, biomass or solid recovered fuels (SRF), with various gasifying and purification technologies.

The range of gas gensets and cogeneration power plants

Our selection of gas gensets and cogeneration units ranges from 60 to 4,500 kWe and is adapted to all types of gases. Thanks to their wealth of functionality, they can produce electricity, hot water, cold steam and hot air.

Our equipment solutions offer:

Whether your company needs steam, hot or cold water, or even hot air, we can offer CHP modules (Combined Heat and Power) that recover the heat from the engine cooling circuits and the exhaust fumes. The standard or made-to-measure Caterpillar CHP modules meet our customers’ needs, irrespective of the configuration of the heating network and the pressures and the temperatures associated with each Cat® gas engine.

Whether your system uses natural gas, biogas or even another type of gas (synthesis gas or hydrogen), we can offer the Caterpillar control and command system that meets your needs. All the automatic control systems of the gensets are based on redundant master-slave microprocessors. The in situ control and command system is operated using a 5.7 to 17-inch touch-sensitive interface.

It does not matter whether your project simply requires regulation of the fuel gas pressure or a safety valve, or whether your biogas requires hydrogen sulphide and/or siloxane treatment, a complete offer of fuel gas supply and treatment systems is available to meet the specific needs of your project.

We offer a range of exhaust fumes treatment solutions that meet all the domestic or international standards. The offer ranges from oxidation catalytic converters that reduce CO2 emissions, to the SCR urea injection systems that eliminate NOx and other contaminants for greenhouse fertilisation.

We propose containerised modular power plants for all types of applications that include soundproofed gensets, electricity distribution and control panels, cooling systems, the lubrication system and ventilation for different ambient conditions. Our personalised containers can be used in Arctic zones at -40°C (-40 °F) or at high temperatures of up to 50°C (122 °F).

Options and accessories:

The range features numerous options and accessories that can be used to personalise your Cat® genset in order to meet your specific needs:

The genset options include:

- high-capacity batteries

- battery cut-out switches

- engine and alternator pre-heating

- anti-vibration devices

- oil level control

The gas genset monitoring and control system options include:

- autostart control panels

- auxiliary controls

- digital control panels

- electronic regulators

- key-operated start-up control panels

- load distributors

- monitoring units

- remote control software

- single/double circuit breakers

- speed controllers

The genset accessories include:

- gas supply rails

- engine exhaust circuits, including the silencer

- engine cooling circuits

- heat recovery circuits

- exhaust fumes treatment systems

- gas and fire detection systems

- metering systems (gas, electricity, heat)

- oil and coolant tanks

- chimneys